Mineral Fiber Ceiling Tiles Manufacturers Just in One Place - The Ultimate Solutions

Want to wholesale mineral fiber ceiling tiles from China?

This ultimate solution guide would help you with everything about wholesaling mineral fiber ceiling products.

What can we offer our customers?

Our company began to produce mineral fiber ceiling tiles in 2002 and has been producing this product for 20 years now. We have a lot of experience with this product, both in production and sales. We are a mineral fiber ceiling tiles manufacturers that make you worthy of cooperation.

After many years of practice, we have summarized the following valuable information, which we hope to be of reference significance for your purchase. Here, you will get an authoritative guide to purchasing mineral fiber ceilings in China. We will give you this article from the following aspects so that your procurement project can be carried out more smoothly.

Quick Get Price&Sample!

Dear customer, first of all, we are very fortunate to meet you here.

Whether you are a new importer who has just entered the mineral fiber ceiling tiles industry or a wholesaler or distributor with many years of experience, we believe that your visit today will be very pleasant. Because it not only provides comprehensive knowledge of mineral fiber ceiling but also covers the detailed information you need before importing or wholesale. Such as mineral fiber ceiling tiles price, mineral fibre ceiling advantages, drop ceiling tiles and many expand knowledge, etc.

At the same time, we also welcome your valuable suggestions as a more professional, so that we can make progress together. Believe that we will be your partner in the future.

To make sure you can find the information you want quickly, we have prepared this content directory that will jump to the corresponding location when you click on it.

Table of Contents

1. Product Description

What is mineral fiber ceiling tile ?

Mineral fiber ceiling tile is a kind of interior decoration & sound-absorbing ceiling tile. Surface color normal is white and black, which shape was square, rectangle.The biggest feature of this ceiling is sound absorption, heat insulation, decoration.

What are mineral fiber ceiling tiles made of ?

The mineral fiber ceiling tiles made of wet-formed Mineral Fiber ,expanded perlite, newspaper, starch, moisture-proof agent, and other additives. It surfaces latex painted finish. Its production process is batching, mixing, molding, drying, cutting, putty, surface spraying, embossing, cutting, second spraying, manual quality inspection, packaging, and storage.

The front of the ceiling colors is white, black, and other custom colors. The back of the ceiling colors is colorless, green, brown, pink, etc. It should also be noted that hbgtceilings have never been manufactured with asbestos.

You can spray code on the back, such as date, brand name, etc. The ceiling has different specifications and patterns, a variety of decorative effects, a variety of artistic styles. Application: commercial office buildings, shopping malls, supermarkets, cinemas, school corridors, hotel lobbies and reception areas, retail stores, galleries and exhibition spaces, machinery rooms, libraries, airports, etc

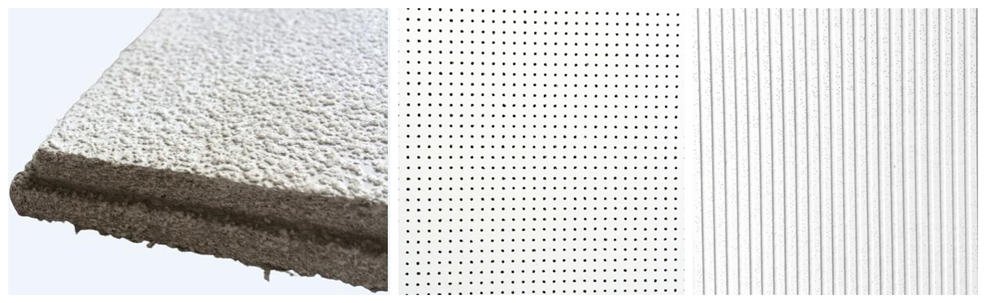

Surface Fiber Ceiling Designs

You can choose from a variety of smooth, textured, and cracked panels designed for acoustic control, versatility, and cost performance. The surface has irregular pinholes, small cracks, and a dune sand surface, which not only contributes to good sound absorption but also creates a modern, high-quality polishing effect. The very fine irregular pore structure forms an eye-catching and elegant ceiling design on the smooth surface, which fits perfectly with the modern design concept.

-

Mineral Fiber Ceiling Glacier

$1.00 Add to quote -

Mineral Fiber Ceiling White

$1.00 Add to quote -

Mineral Ceiling Moon Worm

$1.00 Add to quote -

Mineral Fiber Black Ceiling Tile

$1.00 Add to quote -

Mineral Fiber Ceiling Worm

$1.00 Add to quote -

Mineral Fiber Ceiling 3510

$1.00 Add to quote -

Dune Ceiling Tile

$2.00 Add to quote -

Mineral Fiber Ceiling Star

$2.00 Add to quote -

Pinhole Ceiling Tile

$2.00 Add to quote -

Fine Fissured Ceiling Tile

$2.00 Add to quote

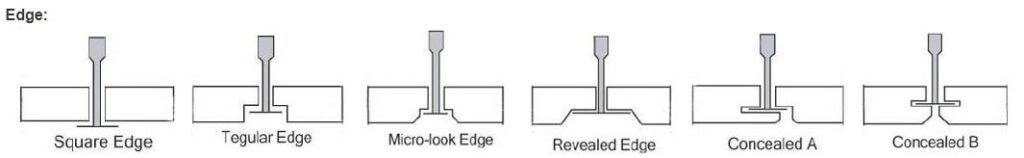

Edges of mineral fiber ceiling tiles

Of various kinds, edges decorate a more beautiful space.To meet the needs of different application environments, our mineral fiber ceiling can provide multiple styles of edges. (SUSPENSION SYSTEM OPTIONS) Edges: Square Edge/Tegular Edge/Microlool Edge/Revealed Edge/Concealed edge

Square Ceiling

Tegular Ceiling Tile

Reveal Ceiling

Microlook Ceiling Tiles

Concealed Ceiling

Mineral Fiber Ceiling Board Specifications

Our products have been tested by the National Building Materials Testing Center. The quality is stable and guaranteed.

Surface Color: White&Black

Density: 240-280KGS/m³

Thickness: 6mm,7mm,8mm,9mm,10mm,11mm,12mm,13mm,14mm,15mm,16mm,18mm,19mm,20mm

Size: 595x595mm,595x1195mm,600x600mm,600x1200mm,603x603mm,603x1213mm,605x605mm,

605x1215mm,610x610mm,610x1220mm,618x618mm,618x1243mm,625x625mm,625x1250mm etc.

Mineral Fiber Ceiling Tiles Main Performance

Surface finish : Factory-applied vinyl latex paint Non asbestos,Non formaldehyde

Fire Performance: B1(China Standard GB8624-2012) Fiber content:>=90%

Sag/Humidity Resistance RH:70%,80%,90%,95%,99% Sound Absorption (NRC): 0.5-0.6

Sound Blocking (CAC):33** Light Reflectance:Minimum LR0.83*

Water content:<=3%

Mineral Fiber Ceiling Tiles Acoustics data:

NRC (Noise Reduction Coefficient)meaning is a standard measurement for a material’s acoustical absorption ranging from 0.00 (no absorption) to 1.00 (total absorption).

CAC (Ceiling Attenuation Class)meaning is a standard measurement of a ceiling system’s ability to block sound between two closed spaces.

Mineral Fiber Ceiling Weight Reference

Normal Export Quality Weight:

10mm=0.95-1KG/PC,11mm=1.02KG/PC,12mm=1.05KG/PC,13mm=1.15KG/PC,14mm=1.2KG/PC,15mm=1.3KG/PC

16mm=1.4KG/PC,18mm=1.5KG/PC,19mm=1.6KG/PC,20mm=1.7KG/PC

Moisture Resistant Ceiling Tiles Weight:

12mm=1.2KG/PC,13mm=1.35KG/PC,14mm=1.4KG/PC,15mm=1.5KG/PC,16mm=1.6KG/PC,18mm=1.8KG/PC,19mm=1.9KG/PC

Mineral Fiber Ceiling Tiles Manufacturing Process

Our mineral fiber ceiling tiles factory established in 2002. Production equipment and technology are the leading positions in the local industry. The range of our mineral fiber ceiling is complete and the quality is stable. We are specializing in the production and export of mineral fiber ceiling and now our daily output of about 30,000 square meters. Our factory has 100 dedicated workers. In order to ensure the quality, we separately test the moisture-proof coefficient(Relative humidity RH%) for each shipment, and we have our own experimental testing equipment. As mineral fiber ceiling tiles manufacturers we have responsibilities and obligations provide customers with stable quality products.

Here are four videos to take a look at the mineral fiber board suppliers you‘ll cooperate:

1. Mineral Fiber Ceiling production line -raw material mix and prepared go to next production process-filter.

2. Mineral Fiber Ceiling production line -Filter mesh production line to filter out water.

3. Mineral Fiber Ceiling production line-The mixture is hardened by forming in a high-temperature furnace.

4. Mineral Fiber Ceiling production line-Press the surface pattern by embossing.

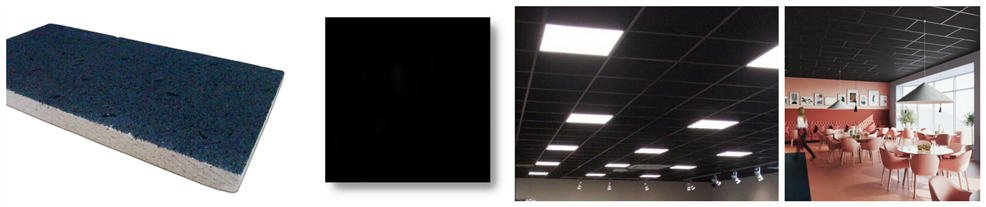

Black Ceiling Tiles Mineral Fiber

Black Ceiling Tiles Mineral Fiber generally refers to mineral fiber ceiling decorative sound-absorbing board. The surface generally has irregular holes (commonly known as: caterpillars) or micro-holes (pinholes), etc. The surface can be painted with various color pastes (the factory products are generally white).

Like the white mineral fiber ceiling, the black ceiling tile has the following advantages:Noise reduction, sound absorption, sound insulation, fire resistance, decoration. Black mineral wool board is generally used in shopping malls, cinemas and other places.

To save you time,we have also prepared a PDF version containing all the mainly contents of this page,only leave your Email and you will get it right now.

2. Questions Before Place Order

Carton Design & Sample Label

The packing method of mineral fiber ceiling tile: four sides are surrounded by carton strips, and the outside is covered with plastic film. The background color of carton strips: White and Brown.The text color of the carton strips: black, green, orange, etc. The carton strips also can print the language content of the logo, and customer country.

At the same time, we can also provide the design of the mineral fiber ceiling tile sample label. The sample label is to make it more convenient for customers to sell locally, which can add LOGO, company name, product specifications and parameters can be printed.

Test report & CE Certificate

Our products have been tested by China’s National Building Materials Testing Center, and all the indexes of the products are up to the standard. The center is the only testing institution in China with a comprehensive inspection capability of building materials products.

Load Quantity By Container

Mineral fiber ceiling this product is light in weight, but it is large in volume. We usually ship the goods by sea and rail.The container loaded can be 20GP,40GP, 40HC,40RF. Below was the container loading quantity of 40HQ. If you need another container load quantity, you can contact us anytime.

Size:600mm*600mm/595mm*595mm/603mm*603mm | |||

Thickness(mm) | PCS/CTN | CTN/40HQ | SQM/40HQ |

11mm | 12PCS/CTN | 1410 | 6091.2SQM |

12mm | 12PCS/CTN | 1278 | 5521SQM |

13mm | 12PCS/CTN | 1220 | 5270SQM |

14mm | 10PCS/CTN | 1278 | 4600.8SQM |

15mm | 10PCS/CTN | 1220 | 4392SQM |

16mm | 10PCS/CTN | 1150 | 4140SQM |

18mm | 8PCS/CTN | 1300 | 3744SQM |

19mm | 8PCS/CTN | 1230 | 3542.4SQM |

Other size load quantity ,please ask our sales | |||

Load goods in container by bulk, pallets, wooden cases

In order to meet the requirements of customers, we provide a variety of styles of loading methods:Bulk, Pallets, Wooden cases,Mix with Grid.

FCL: This is the most commonly used method of loading, manually loading the packed mineral fiber ceiling tiles into the container

Pallets: Made of plywood pallets and do not contain solid wood. The packaged Mineral fiber ceiling is placed on the pallet and will be wound around with plastic film to ensure that the goods do not shake between the pallet and the goods. We calculate the appropriate packing volume according to the height of the container. But the quantity packed in pallets is certainly less than that in bulk.

Wooden cases:The wooden case is also made of plywood, without solid wood, and is a closed wooden case. The cost of wooden cases is much higher than that of pallets, and the packing capacity is also limited. Suitable for bulk mineral fiber ceiling.

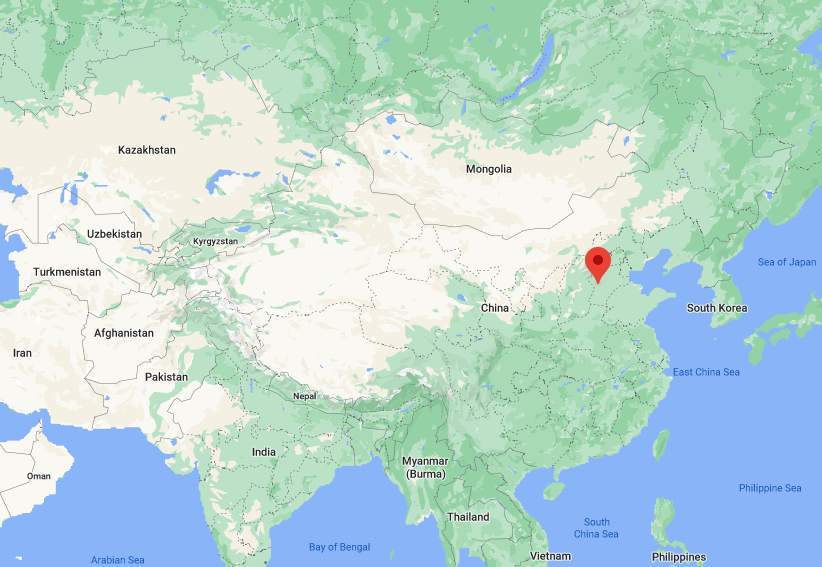

Production Location & Shipping Port

Our Mineral Fiber Ceiling Tiles factory was located in Shijiazhuang, Hebei Province China. The nearest airport to our factory is Shijiazhuang Airport. It takes 1.5 hours to get to our factory by car from the airport. The nearest railway station to our factory is Shijiazhuang Station. It takes 2 hours to get to our factory by car from the railway station.

Our loading port is XINGANG,Tianjin China.It takes about 7 hours for the truck to load the container from our factory to Tianjin Port.Basically, after loading in the morning, the container will arrive at the port in the evening.

The location of the red arrow is our mineral fiber ceiling factory

Which countries do mineral fiber ceiling tiles manufacturers export to?

Since 2002years, we began to produce. Since 2009 years, we began to export.

Export more than 50 countries. Look forward to working with more customers from other countries.

Until December 2022, we have exported Mineral Fiber Ceiling Tiles to the following countries:

East Asia: Mongolia.

Southeast Asia: Philippines, Vietnam, Thailand, Malaysia, Brunei, Singapore, Indonesia.

South Asia: Nepal, Bangladesh, India, Pakistan, Sri Lanka.

West Asia: Iraq, Syria, Israel, Turkey. .

Southern Europe: Italy, Malta, Spain.

Africa: Kenya, Tanzania, Ghana, Namibia, South Africa.

Oceania: Australia.

North America: Canada, United States, Mexico, Guatemala, Honduras, Costa Rica, Panama, Trinidad and Tobago, Puerto Rico. South America: Colombia, Venezuela, Ecuador, Peru, Bolivia, Brazil South Chile, Argentina, Uruguay, Paraguay

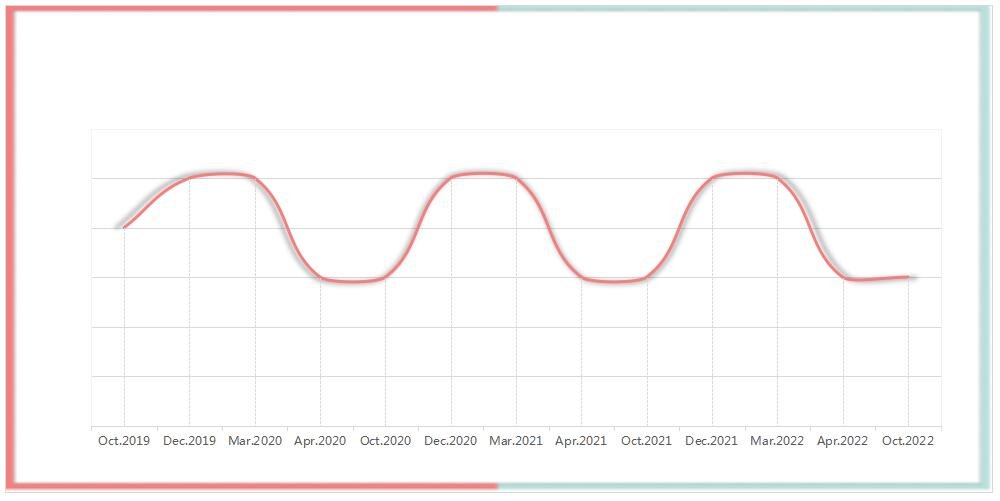

Mineral Fiber Ceiling Tiles Price Trends

In fact, the price of mineral fiber ceiling tile also changes regularly. We believe that importers or wholesalers who purchase regularly will know this situation. In order to allow more customers to purchase when the price is right, so as to reduce the import cost, then you need to learn the changes of factory price or suitable mineral fiber ceiling tiles price.

The price from “April-October” every year is relatively stable and suitable for purchase;

From “November-March” of the second year, the price is the high of the whole year;

In addition to the factors of raw materials, the price will fluctuate mainly due to the impact of energy. The mineral fiber ceiling tile production line relies on natural gas for heating and production, so the rise or fall of natural gas prices affects the price of mineral fiber board.

Our factory is located in northern China. Every November to March of the next year is the winter in our city. Our city residents need natural gas for heating in winter. Therefore, in this special period, natural gas is not only required for residential production to supply heat, but also for industrial production. This leads to an imbalance between supply and demand. Prices went up. The price of the mineral fiber ceiling has also risen.

Therefore, we will regularly remind importers or wholesalers to adjust their purchasing plans to avoid unnecessary cost increases.

If you want to get the mineral fiber ceiling tiles price now, then please provide the following information, our sales will contact you within 10 minutes. Quote need:

Size/Thickness/Edge/Quantity/RH%/Packing

Mineral Fiber Ceiling Tiles Payment Terms

International mainstream payment methods, we are all acceptable. For example: T/ /letter of credit, etc.

3. Mineral Fiber Ceiling Tiles Factory Show

Our Factory Established in 2002.

Export department was set up in 2009.

Up to 2022, we are still engaged in the production ceilings system.

Production equipment and technology are the leading position in the local industry.

The ranges of mineral fiber ceiling tiles are complete and the quality is stable.

Our sales team can communicate in English and have rich export experience to help you complete the purchase smoothly.

4. Ceiling Tiles Installation

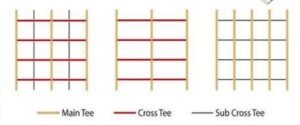

Matching Dimensions Of Ceiling Grid Installation

Customers in different countries have preferences for the choice of size. In order to ensure the smooth installation of the project, we need to have a certain understanding of the matching size of the mineral fiber ceiling tile and ceiling grid, so as to avoid some mistakes. If the size you want to purchase is not available here, you can contact our sales.

Mineral Fiber Ceiling Tile Size | Ceiling Grid Main Tee | Ceiling Grid Long Cross Tee | Ceiling Grid Short Cross Tee | Ceiling Grid Wall Angle |

595mmx595mm | 3600mm | 1200mm | 600mm | 3000mm |

600mmx600mm | 3630mm | 1210mm | 605mm | 3000mm |

603mmx603mm | 3660mm | 1220mm | 610mm | 30000mm |

610mmx610mm | 3075mm | 1230mm | 615mm | 3000mm |

610mmx1220mm | 3690mm | 1230mm | 3000mm |

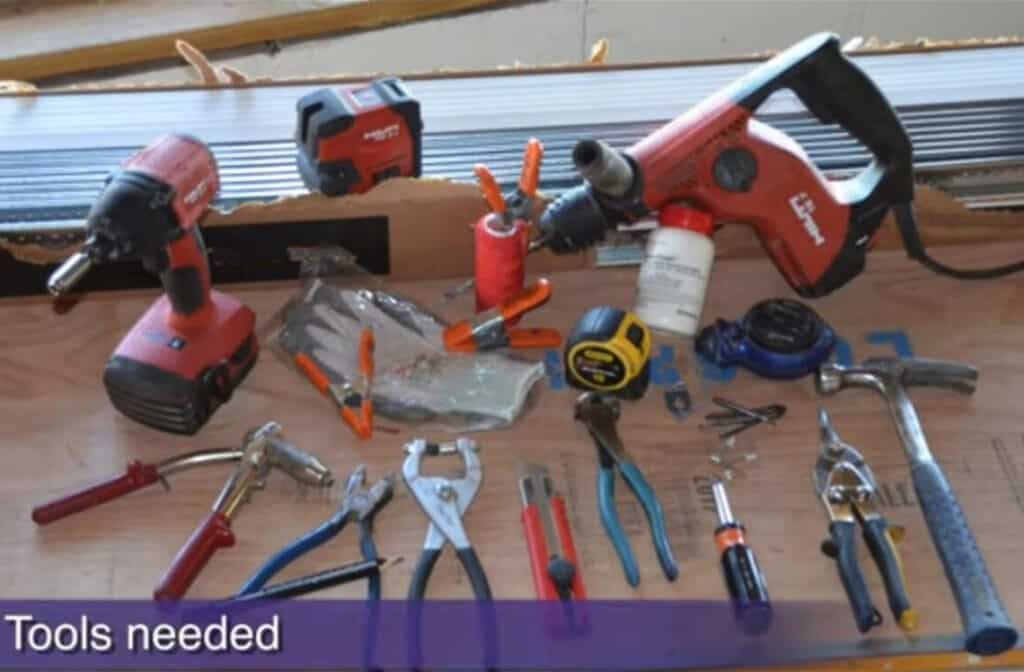

What materials do you need for mineral fiber ceiling installation?

- Cut resistant gloves/Safety glasses/Hard hat

- Cordless drill, screw tips& drill bits

- Ladder, rolling scaffold

- Snips-metal cutting tin snips

- Laser-horizontal line leveling

- Hole punch/pop riveter

- Lineman pliers with wire cutter

- Hammer

- Chalk line

- 10.Screwdrivers-slotted/Phillips

- Tape measure

- Spring clamps

- Utility knife

- String-for control/dry line

- Carpenter pencil

- Tool belt/nail apron

- Aluminum white pop rivets

- Compass/ handed hole saw

- Screws, fence staples, or anchors for wall angle

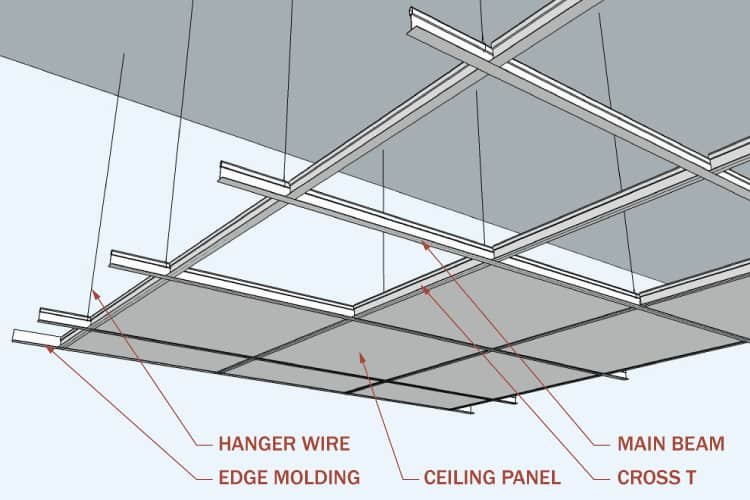

How to mineral fiber ceiling installation?

Installing a beautiful ceiling is surprisingly easy with the right tools and a little know-how by following these simple steps and tips you can ensure a perfect finish like this one for your space.

Please reference the below “Installation Instructions”

Part 1: Before installation begins measure your walls and use graph paper to draw the room to scale.

Part 2: Tools Needed

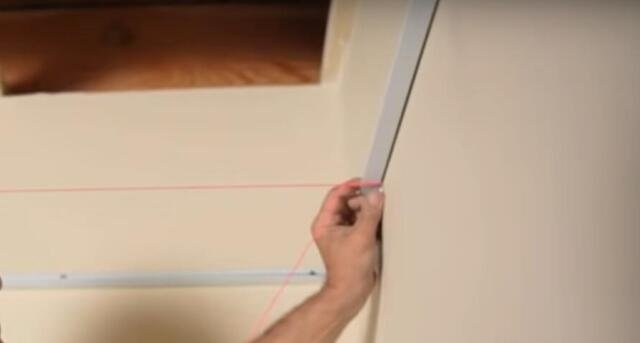

Part 3: Find the position of the horizontal line

A laser is crucial to use when installing a ceiling.As well make sure your level line laser is set to the fin height of your ceiling

this is the line that we will hang our wall angle.

Part 4: Start installing the corner-Wall Angle

4.1 At first, we must hammer drill holes for tap-in anchors as we hang our wall angle to the red laser line.

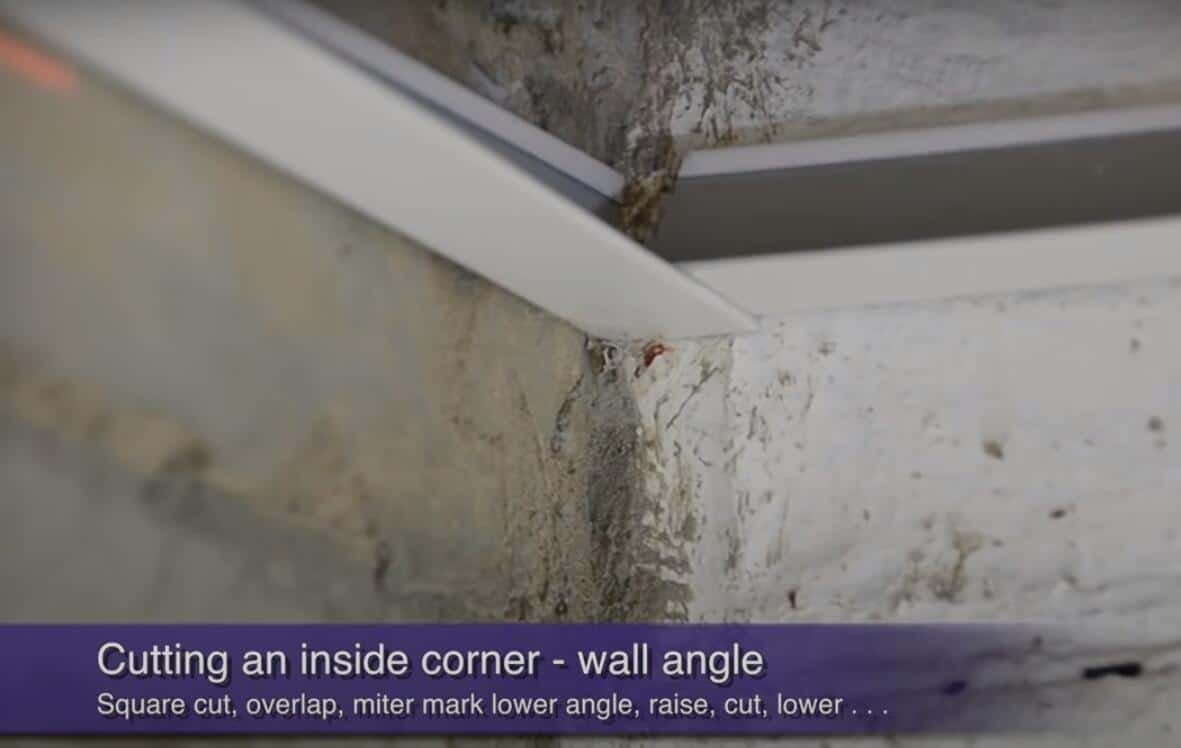

4.2 When you get to your inside corners a finished 45-degree miter is a much more pleasing visual than simply overlaying.

4.2 When you get to your inside corners a finished 45-degree miter is a much more pleasing visual than simply overlaying. Cuts all you have to do is mark and cut a 45 degree on the lower angle then overlay the butt cut upper angle for a perfect

Cuts all you have to do is mark and cut a 45 degree on the lower angle then overlay the butt cut upper angle for a perfect

mitered visual from below.

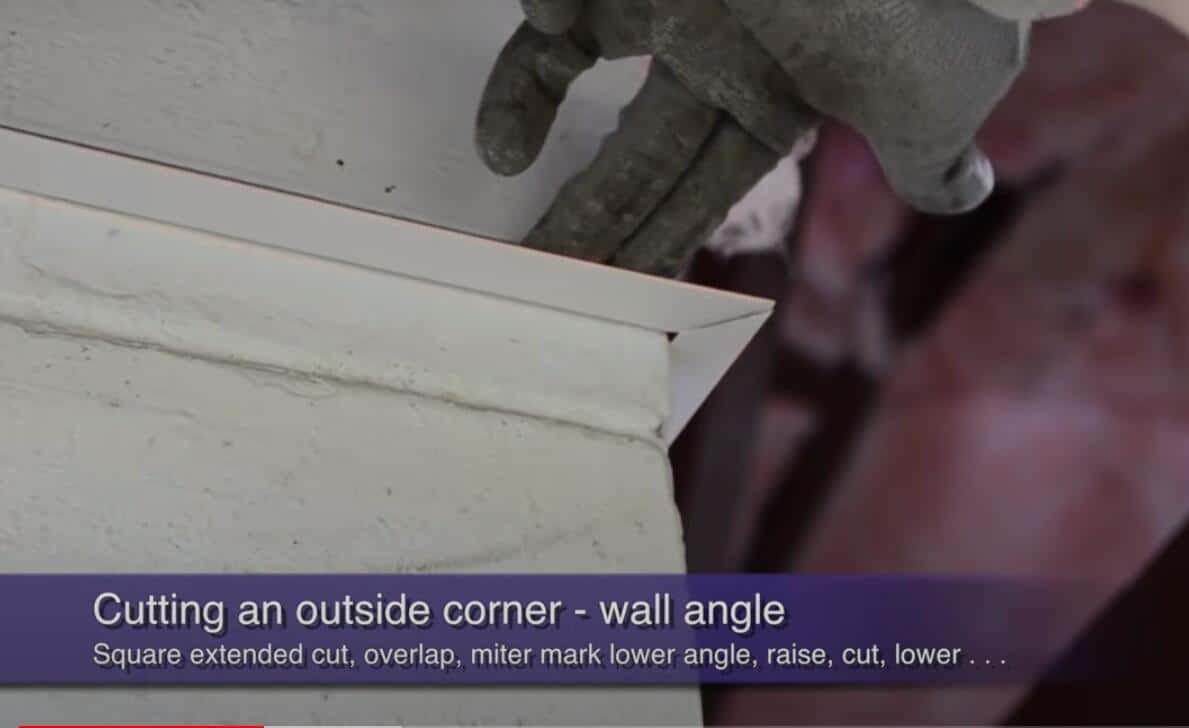

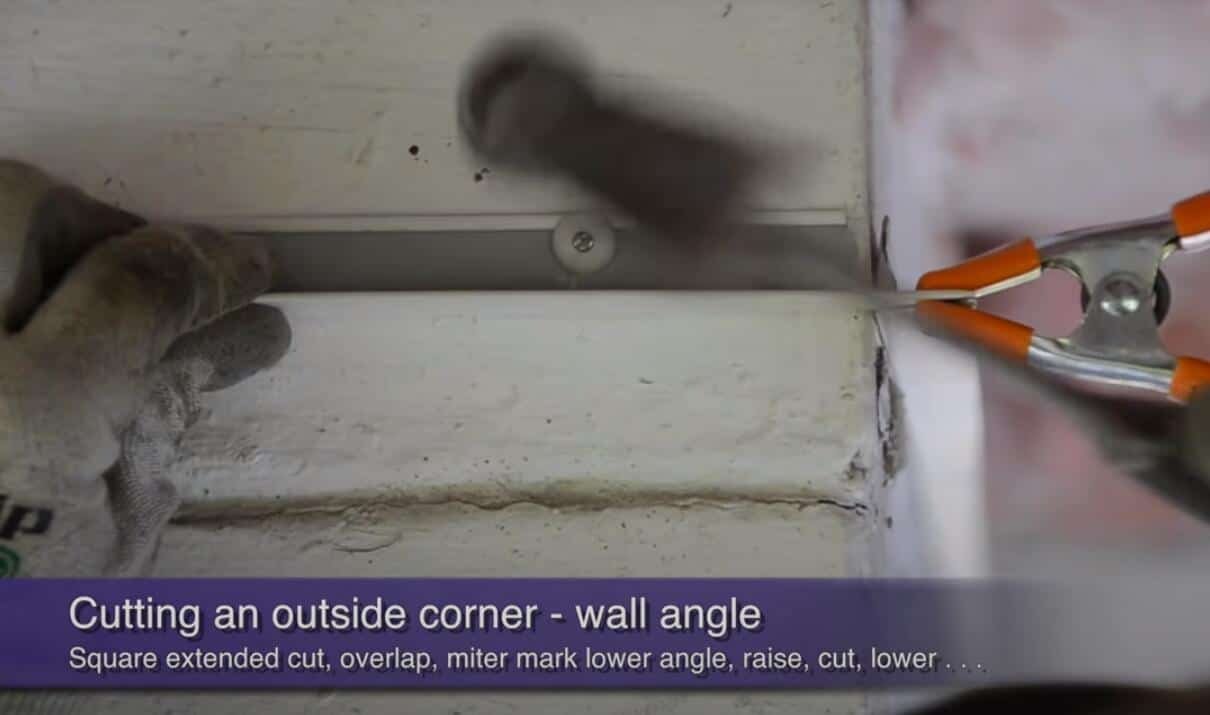

4.3 The outside corners require a little more attention but are still easy to achieve a clean mitered visual. Simply let the angle override past the corner then square but cut to length. Next you want to cut away the vertical flange leaving an

4.3 The outside corners require a little more attention but are still easy to achieve a clean mitered visual. Simply let the angle override past the corner then square but cut to length. Next you want to cut away the vertical flange leaving an

exposed horizontal tab you will do this to both angles that approach the outside corner after overlaying them at the corner mark. Finished with a corner that looks perfectly mitered but is still structurally sound a spring clamp will hold the corner into place while you do the final attachment to the wall .

Finished with a corner that looks perfectly mitered but is still structurally sound a spring clamp will hold the corner into place while you do the final attachment to the wall .

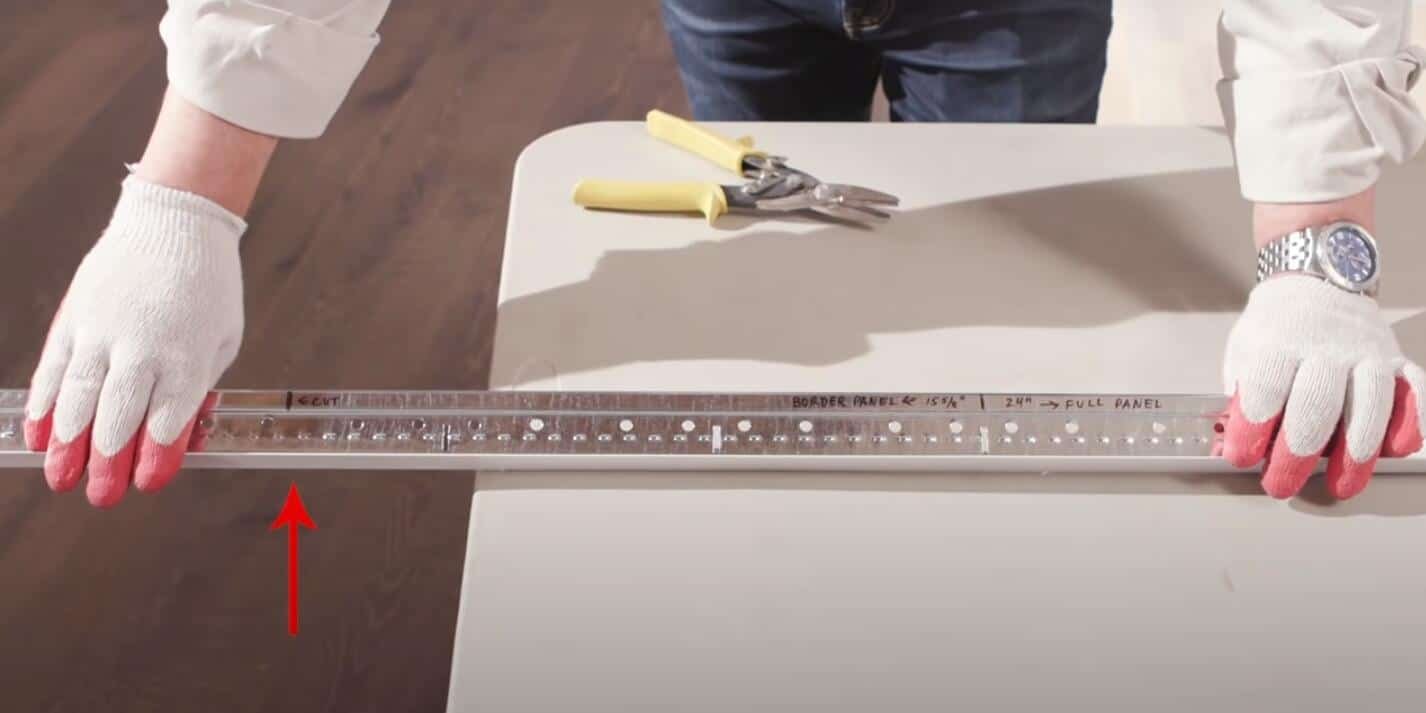

Part 5: Now let’s figure out what width our perimeter border ceiling panels should be, this will help us determine our ultimate grid layout.

Part 5: Now let’s figure out what width our perimeter border ceiling panels should be, this will help us determine our ultimate grid layout.

It’s important to install two perpendicular dry lines or control line strings to serve as a perfectly square benchmark to install our grid off of.

Stretch string across the room in each main tea location,to do this pull a string taut as you insert nails or pop

Stretch string across the room in each main tea location,to do this pull a string taut as you insert nails or pop

rivets attached at each end between the wall and the wall angle on the opposite wall locations stretch one string

perpendicular to the main T’s to mark.

Part 6: Attach a hanger wire

Part 6: Attach a hanger wire

You will do final leveling once all of the grid is installed.Preparing and hanging main tee.

Part 7: Install the main tee

Part 7: Install the main tee

7.1 You will need to trim the end of the first main tee. This first main beam should be closest to the wall.

Cut the top of the grid first with tin snips. Then bend the grid open and cut the face.

Place the cut end of the main beam on the wall molding.

Place the cut end of the main beam on the wall molding.

7.2 Using the round hole in the grid, hang the main beam on the hanger wire or Quick Hang hook. After installing the main tee ,check to make sure your grid is level after re-bending the wire. Do this same step for the next main tee install.

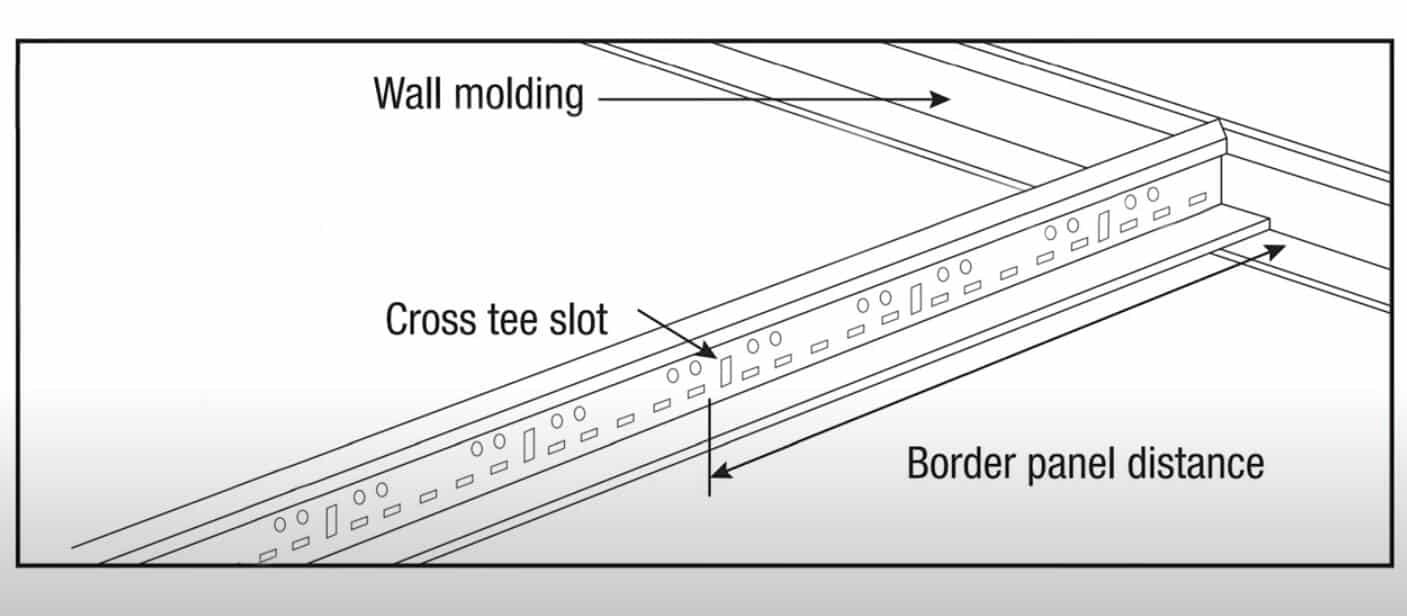

7.2 Using the round hole in the grid, hang the main beam on the hanger wire or Quick Hang hook. After installing the main tee ,check to make sure your grid is level after re-bending the wire. Do this same step for the next main tee install. Part 8: Preparing and cutting Boarder Cross Tee Your first border tee will be positioned a border panel’s distance away from the wall.

Part 8: Preparing and cutting Boarder Cross Tee Your first border tee will be positioned a border panel’s distance away from the wall.

To cut the first border tee, hold the end of the cross tee against the wall, and then mark and cut the cross tee where it intersects the string line. Insert the uncut end of the cross tee into the main tee.

To cut the first border tee, hold the end of the cross tee against the wall, and then mark and cut the cross tee where it intersects the string line. Insert the uncut end of the cross tee into the main tee.

Repeat these steps for the second border cross tee. Part 9: Squaring the Grid

Repeat these steps for the second border cross tee. Part 9: Squaring the Grid

To achieve the best results. It is important to make sure your grid is square at this point in the installation.

This will allow you to adjust if changes are required. Before checking for squareness, you

should first install two 4-foot cross tees between the two main beams in line with the first two border tees.

Part 10: Cut and install all remaining border 600mm cross tees.

Part 10: Cut and install all remaining border 600mm cross tees.

Part 11: Installing ceiling panels

Wear clean gloves or wash your hands before you handle the ceiling panels to prevent dirt smudges on the tiles.Lift the panel at an angle up through the grid. Gently drop into place.

Remember, mineral fiber panels can be delicate and should be handled with care. Avoid dragging the face or edges of the panels against the grid. Start with border panels and work towards the center of the room.

The above are the introduction of the steps for hoisting the mineral wool board, we hope this information is helpful to you!

The above are the introduction of the steps for hoisting the mineral wool board, we hope this information is helpful to you!

How do you clean mineral fiber ceiling tiles?

- The surface of mineral fiber ceiling tile produced by the Chinese supplier is sprayed with latex paint without film, so the dust on the surface can only be wiped with a dry rag. Please be careful not to damage the structure of the mineral fiber ceiling when cleaning.

- Most of the mineral fiber ceiling tiles are not waterproof, so do not wipe with water-containing things, it will sag and deform.

- Do not scrub with tools such as hard objects and cleaning balls, because this will leave scratched small strips on the bright panel, which will affect the aesthetics of the mineral fiber ceiling.

- Use a small brush to clean the seam of the mineral fiber board.

- If the mineral fiber ceiling board is soaked by air-conditioning condensate or other leaking water, it must be replaced in time to avoid more losses.

5. Mineral Fiber Ceiling Resources

Mineral Fibre Ceiling Advantages

1. No asbestos, no formaldehyde

The mineral fiber ceiling uses high-quality mineral wool as the main raw material, 100% asbestos-free, no needle-like dust, and will not enter the body through the respiratory tract, and is harmless to the human body;

2. Fire resistance

Mineral fiber ceiling tile is made of non-combustible mineral wool as the main raw material. It will not burn in the event of a fire and can effectively prevent the spread of fire. It is the most ideal fireproof ceiling material, especially suitable for use in public places and high-rise buildings. middle.

3. Sound absorption and noise reduction

The mineral fiber ceiling is a kind of porous material composed of fibers with numerous micropores, which can effectively reduce the reflection of sound waves, eliminate echoes and isolate the noise transmitted by the floor. When the sound wave hits the surface of the material, part of it is reflected back, another part is absorbed by the plate, and part of it passes through the plate and enters the back cavity, which greatly reduces the reflected sound and can effectively control and adjust the indoor reverberation time, thereby reducing noise. Noise reduction, sound absorption, sound insulation.

4. Surface good decoration

The surface of the mineral fiber ceiling tile has effects such as knurling and embossing, and the patterns include gypsophila, caterpillars, cross flowers, central flowers, walnut patterns, stripes, etc. Consumers can choose according to their personal preferences, and the decorative effect is also very good. beautiful.

Mineral fibre ceiling disadvantages

1.Easy to damage: Because the mineral fiber ceiling tile has good sound absorption and noise reduction characteristics, in order to strengthen this feature, it needs to be punched during production, which leads to a lower strength of the mineral fiber ceiling, which is very difficult to decorate easily damaged.

2. Easy to change color: The surface of the mineral fiber ceiling tile is mainly white, which is easily affected by other volatile solvents and yellowing, and the yellowing will affect the appearance. It is recommended to installation the mineral fiber ceiling at the end.

3. Surface chromatic aberration: The decorative effect of mineral fiber ceiling tile is very nice, but when spraying, many times due to the process problems of different production factories, the effect of spraying varies, and it is easy to appear chromatic aberration, so when purchasing be sure to choose carefully to avoid chromatic aberration that affects the appearance.

4. Not waterproof: Mineral fiber ceiling tile is not waterproof, so special attention should be paid during transportation, installation and daily maintenance.

5. Easy to sag: The general installation environment can not exceed 40°C, and the humidity requirements are high. The ordinary quality can adapt to the relative humidity of about RH80%, but the moisture resistant ceiling tiles can adapt to the relative humidity of RH90-99%. Therefore, if the ceiling installation environment is very humid, it is recommended to purchase moisture resistant ceiling tiles.

Are mineral fiber ceiling tiles safe?

Mineral fiber ceiling tiles are safe, why? Because the mineral fiber ceiling tiles are made of wet-formed Mineral Fiber, expanded perlite, newspaper, starch, moisture-proof agent, and other additives which raw materials no asbestos, no formaldehyde, harmless to the human body.

Mineral wool ceiling tiles slag is melted at high temperature and the flocs thrown out by high-speed centrifuge are harmless and pollution-free. It is a green building material that turns waste into treasure and is beneficial to the environment. It is a new type of environmentally friendly building material with various functions such as decoration, sound absorption, heat preservation, heat insulation, fire prevention, and lightness.

The mineral ceiling tiles are made of slag wool as the main raw material, adding the appropriate amount of additives, and processed through batching, molding, drying, cutting, embossing, veneer, and other processes.

The biggest feature is that it has good sound absorption and heat insulation effects. The surface has the effects of knurling and embossing, and the patterns include gypsophila, caterpillars, pinhole ceiling, fine fissured ceiling tile, black ceiling tiles, sand dune ceiling tile, and so on.

The mineral fiber ceiling tile production line introduces advanced Japanese production technology and selects the main raw material mineral fiber to be refined from recycled slag, and the added organic fiber is recycled from old newspapers. The waste generated by processing and the old ceiling that completes the life cycle of the product can be recycled (the highest recycled material is 79%), which effectively reduces construction waste and avoids environmental pollution.

So the mineral fiber ceiling tiles are safe and are a good choice for commercial ceilings.

What causes mineral fiber ceiling tiles to sag?

The reasons for the sagging ceiling are mainly related to the quality of the mineral fiber ceiling tile itself、the ceiling installation

environment、and ceiling grid installation methods.

1. Moisture resistant ceiling tiles: The main index of the subsidence of the mineral fiber board is the moisture deflection. The

higher the moisture resistance level, the smaller the subsidence deformation. Therefore, when choosing, it is necessary to

combine the local environmental humidity to select the corresponding RH% quality products.

2. Ceiling installation environment: These environments will cause sagging, so try to avoid the use of mineral fiber board ceiling. Such as: high temperature environment where the temperature is too high, exceeding 40°C; Indoor water accumulation,

environment in direct contact with water; Indoor air humid swimming pool area, shower room, changing room, special production area (such as textile factory) and building, the place where the object is not completely sealed.

3. Mineral fiber false ceiling size: The ceiling has different specifications, such as length 600, 1200, 1800mm, width 300, 400,

600mm. In the process of use, we found that the size of 600×600mm is rarely deformed because the “ceiling grid “is overlapped

around it and the stress is evenly distributed. The most serious subsidence deformation is the strip plate, such as

300/400×600/1200/1800mm, 600×1200/1800mm, etc. These specifications of the mineral fiber ceiling board have high

requirements on the quality . If there are no special decorative requirements, try to avoid choosing Strip mineral fibre board

ceiling.

4. Fiberboard ceiling storage environment: Because the mineral fiber ceiling tile is very easy to absorb moisture and deform, the mineral ceiling board should take corresponding measures during transportation, installation and storage to prevent moisture deformation. In particular, storage is an easily overlooked link for ceiling deformation, and special attention should be paid to it, otherwise it will be deformed before installation, which will cause unnecessary material waste and economic losses.

5. Irregular ceiling installation methods: In the project, we found that the construction team often adopted cross-operation

methods in order to catch up with the construction period, such as indoor wall painting or door and window installation and

ceiling installation at the same time. If the interval between wall painting and ceiling is short, because the wall is not dry, the

indoor humidity is too high, and the mineral fiber acoustic ceiling tiles that has been hoisted will absorb moisture and deform. In the rainy season, the ceiling should be installated after the doors and windows closed. If it is not closed, the outdoor moisture will aggravate the deformation of the mineral ceiling tile.

6. Ceiling grid installation : When installing the mineral wool ceiling tile, no other materials should be placed on the mineral wool board to prevent the board from being deformed under compression. The connection between the hanger and the ceiling grid should be firm, otherwise the hanger and the ceiling grid will be loosened, which will lead to stress Concentration, resulting in large deflection and deformation, and large-area cover panel unevenness. Heavy lamps, electric fans, and exhaust fans are objects with dynamic loads, which should be fixed by independent suspension rods to prevent the ceiling frame system from loosening due to vibration, which in turn leads to mineral ceiling tiles surface is not flat.

What to do if ceiling is sagging?

If the mineral fiber ceiling tile is sagging, first of all, no matter what the reason is, within 3 days of the board sagging, you need to take off the board immediately, put a table in the room, stack the removed board on the table and press it on it. After a week, the board can be taken out and used directly, which can minimize the loss.

Mineral fiber ceiling is a sound-absorbing product. While absorbing sound, it also absorbs water due to density and other reasons. Generally, after the mineral ceiling tiles is hoisted, if it does not sag within half a month, the board will not sag again. The process of adapting the mineral wool ceiling tiles to the installation environment and saturating its own moisture content, because once the mineral fiber ceiling adapts to this installation environment, the moisture of the board itself is saturated, and even if the environment is humid, it will not sag again.

How do you prevent mineral fiber ceiling tile from sagging?

In order to prevent mineral fiber ceiling tile from sagging , we should pay attention to the following aspects:

1.Suitable temperature and humidity:Mineral Fiber Ceiling belongs to interior decoration products, the normal room temperature during installation and construction is not more than 40°C, after the completion of indoor painting and other damp projects, the construction environment is dry and ventilated, and the relative humidity meets the requirements of the products. When there is stagnant water in the room, it is recommended not to installation.

2. Interior decoration and ceiling installation cannot be done at the same time: Mineral fiber board is the last part of interior decoration. The ceiling step should be done after various pipelines, lamps, air conditioning, heating system, doors and windows, glass and other projects are completed, and the room should be dry. Finally is the mineral fiber ceiling tile installation.

3. Special environmental requirements:Indoor environment containing chemical gases or vibration is not suitable for installation, some chemical gases are easy to yellowing the surface of mineral fiber ceiling board.

4. Nothing can be placed on the surface:Do does not cover the thermal insulation material on the Mineral Fiber Ceilings, the bearing weight is excessive, which may cause the mineral fiber false ceiling to sag.

5. Moisture resistant ceiling tiles choice: Mineral fiber board ceiling should not be used in the most exciting wet areas. If there are special requirements for humid environments, please choose products with a higher moisture resistant ceiling tiles.

6. After the installation, matters need attention: After installation, please keep it ventilated, clean and dry to prevent the mineral fiber ceiling from sagging or contaminated by moisture.

7. Damp or wet ceilings, replace in time:If the acoustic mineral fibre ceiling board has been soaked in air conditioning condensate or other leaks, it must be replaced in time so as not to cause more losses.

8. Storage Environment Requirements:The storage environment of the mineral fiber suspended ceiling is clean, dry, ventilated, pay attention to Rain Water, beware of its moisture absorption deformation.

9. Can not be installated on rainy days:Can not lay floor tiles and false ceiling mineral fiber board at the same time, to first lay floor tiles, in the ceiling. (not even in dry areas). Can not be cloudy, hoisting during the rain, can not be hoisted while raining, otherwise, it is easy to sag.

Mineral Fiber Ceiling Tiles hs code

For export from China Customs, the hs code we use now is: 6806109090. Before importing, customers can check the tariff situation with the local customs in order to calculate the import cost.

What should we do if the surface of the mineral fiber ceiling turns yellow?

In most cases, this is a problem that occurs after the Mineral Fiber Ceiling Tiles has been used for a long time, just like the clothes will change color after wearing for a long time, the Mineral Fiber Ceiling Tiles has been exposed to the air for too long

will turn yellow. At this time, we have to consider how to deal with these discolored mineral fiber board. Can the Mineral Fiber Ceiling with this problem be refurbished? Can it be covered with latex paint?

First of all, we must understand why the Mineral Fiber Ceiling Tiles turns yellow and discolored? There are two possible reasons for yellowing:

1. The quality of the mineral fiber ceiling tiles are not good, or the color of the paint is not correct. This situation is more common when the mineral fiber ceiling is unpacked and installed at the project place. When there is a problem with the material of the mineral fiber board ceiling, or the quality of the material selected for coating treatment is poor, after the mineral fiber board ceiling is hoisted and installed, it will oxidize and change color after contact with the air. There are also mineral fiber ceiling that have been used for a period of time and have not yet passed the product quality warranty period. For this problem, we recommend that users return and exchange the product directly. When there is a problem with the color of the mineral fiber ceiling, the internal material ratio will also have certain problems. Even if it continues to be used, other quality problems may occur.

2. The mineral fiber ceiling tiles has been used for too long, and the surface discoloration is normal situation. When faced with this situation, it is generally recommended that customers directly remove and replace the mineral fiber ceiling tiles. Of course, some customers use latex paint to cover the discolored mineral fiber ceiling surface in order to save costs. This method is not recommended, because although the use cost is relatively saved, because the mineral fiber ceiling is directly hoisted by ceiling grid installation. Direct brushing of latex paint is likely to cause uneven application in many places, which can easily affect the aesthetics of the mineral fiber ceiling tiles and the sound absorption and sound insulation performance of the mineral fiber ceiling tiles will be reduced after painting, so please use this method with caution.

Mineral fiber ceiling tiles appear discolored, and the internal structure of these boards has changed to a certain extent, which is likely to cause safety hazards. In the case of not affecting the appearance and normal use, it is recommended that the user reasonably consider the cost of the mineral fiber ceiling tiles and then replace them.

Why do mineral fiber ceiling tiles have holes on surface?

The raw material of mineral fiber ceiling tiles are mainly mineral wool. Mineral wool has many micropores. These holes can effectively eliminate echoes and isolate noise. Therefore, mineral fiber ceiling tiles also have the characteristics of sound absorption and noise reduction. Because of this feature, it is very suitable to use mineral fiber ceiling in commercial and home improvement. Especially in some public places, such as schools, hospitals, shopping malls, etc.

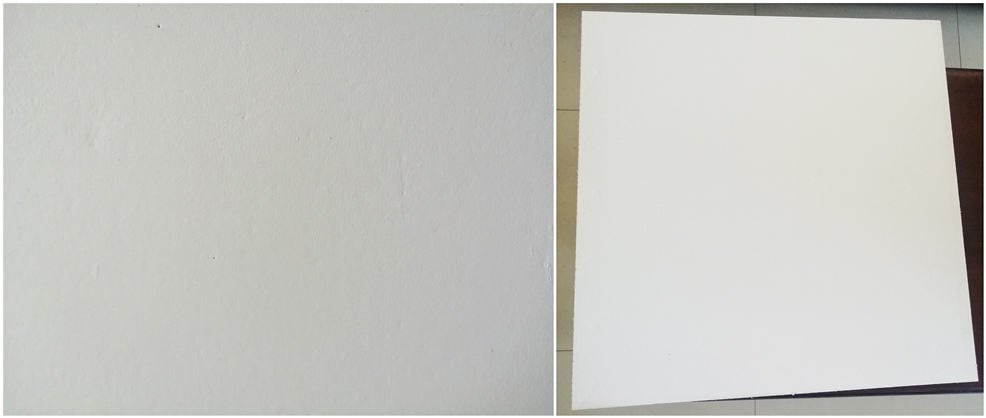

Why are smooth ceilings more expensive?

The smooth mineral fiber ceiling tile surface has no pattern, just a pure white surface. Just like the picture.

This smooth surface cannot hide any flaws, and even small scratches can be seen clearly. So this requires our production workers during the quality inspection, the board with scratches or defects is thrown away and recycled, which increases a lot of labor and production costs. However, if the surface is printed with patterns, some small scratches can be blocked, which can also reduce waste, improve the utilization rate of products, and reduce the cost.

So smooth mineral fiber ceiling tiles are more expensive.

6. Ceiling Tile Options

Fiberglass ceiling tiles vs Mineral fiber ceiling tiles

1. Raw Material:

The main raw material of mineral fiber ceiling tile is slag wool.

The main raw material of fiberglass ceiling tile is fiberglass.

2. Surface Treatment:

The surface of the mineral fiber ceiling generally has many kinds of regular holes or micro-holes (pinhole ceiling), and the surface can be painted with various color pastes (the factory products are generally white). The surface is pressed with different patterns, which has a strong decorative effect.

The surface of the fiberglass ceiling tile is affixed with a layer of glass fiber mat, and the surface treatment form is single, generally plain or with dots, and there are generally only two kinds of dots with dots, which can be painted in various colors (the integrated ceiling is generally white, and the suspension is often optional).

3. Product Density:

The conventional density of mineral fiber ceiling is the common density of 240-280KG/m3

The common density of fiberglass ceiling tile is 90-160KG/m3

4. NRC (Noise Reduction Coefficient):

In terms of sound absorption effect of mineral fiber ceiling, the commonly used density is about NRC 0.55; in order to achieve the same sound absorption performance of glass fiber board, the density needs to be reduced, which will affect its quality.

In terms of sound absorption effect of fiberglass ceiling tile, the commonly used density is NRC 0.8-0.95, filamentous and porous, and the sound absorption effect is better.

5. Product Thickness:

Mineral fiber ceiling thickness range is: 6mm, 7mm, 8mm, 9mm, 10mm, 11mm, 12mm, 14mm, 15mm, 16mm, 18mm etc.

Fiberglass ceiling tile thickness range is:12mm, 15mm, 20mm, 25mm for integrated ceiling, and 30mm-50mm for suspension.

6. Suitable for hoisting places:

Mineral fiber ceiling is generally used in commercial office buildings, shopping malls, cinemas, hospitals, airports, etc.

Fiberglass ceiling tiles are mainly used in theaters, concert halls, museums, exhibition halls, libraries, galleries, gymnasiums, lecture halls, hotel lobbies and other places that require high acoustic environment and high-end decoration.

7. Fire resistance:

Mineral fiber ceiling is Class B1 grade.

Fiberglass ceiling tile is ClassB1 and Class A.

8. Product Price:

Mineral fiber ceiling tiles price belongs to the mid-lower-end price.

Fiberglass ceiling tile price belongs to the middle and high-end price.

PVC Gypsum Board vs Mineral Fiber Ceiling Tiles

1. Raw Material:

The main raw material of PVC gypsum board is a normal gypsum board.

The main raw material of mineral fiber ceiling tile is slag wool.

2. Surface Treatment:

The surface of the PVC gypsum board is PVC film, the back is aluminum foil, and the middle is gypsum board.

The surface of the mineral fiber ceiling generally has many kinds of regular holes or micro-holes (pinhole ceiling), and the surface can be painted with various color pastes (the factory products are generally white). The surface is pressed with different patterns, which has a strong decorative effect.

3. Product Thickness:

PVC gypsum board normal thickness: 7mm, 7.5mm,8mm,9mm,12mm

Mineral fiber ceiling thickness range is: 6mm, 7mm, 8mm, 9mm, 10mm, 11mm, 12mm, 14mm, 15mm, 16mm, 18mm etc.

4. Fire resistance:

PVC gypsum board and Mineral fiber ceiling are both Class B1 grade.

5. Product Price:

PVC gypsum board price is cheaper than mineral fiber ceiling.

6. Sound absorption:

PVC gypsum board does not have the sound absorption performance of mineral fiber ceiling. It is mainly decorative performance and moisture resistance better than mineral fiber ceiling.

How to get samples online or by email?

We can provide samples free of charge, you just need to tell us the specific requirements, such as thickness, sample size, design and color, qualitystandard, quantity. So we can confirm the approximate weight. At the same time, you are required to provide the pick-up address and zip code so that we can confirm the express fee. If you have any other questions, you can contact our sales.